C E L M E T R I X

.png)

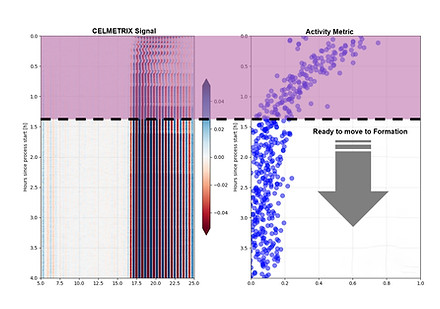

Real Time Quality Control in Battery Production

Discover how CELMETRIX transforms manufacturing lines by reducing scrap and detecting defects early.

Electrolyte Fill Monitoring

Monitoring the filling stage in battery manufacturing is critical because inconsistencies at this point directly affect cell performance, safety, and lifespan. CELMETRIX’s rapid, inline monitoring technology uses advanced edge analytics to assess fill quality in real time. These actionable insights enable early detection of deviations, optimise process control, reduce waste, and improve overall production quality and yield.

Early Gas Detection

Early gas detection in battery cells is essential because gas build-up often indicates internal defects, safety risks, or manufacturing issues. CELMETRIX's fast, multi-point inline sensing combined with advanced edge analytics enables real-time identification of gas-related anomalies. This early warning capability enhances safety, reduces rework, and ensures that only high-quality cells move forward in the production process.

Interested to find out more?

Wish to contact us?

Email us here:

Or you can find us here:

STEAMhouse, Belmont Row,

Birmingham B4 7RQ